FX-DX was commissioned to design an improved version of a fiber optic processing unit that no longer met current performance criteria.

Initially, the idea was to make physical modifications to the system, but as we looked at the customer’s process, we realized that it was possible to simplify a few steps and make it more efficient.

This is a concrete example of a project involving the optimization of existing processes.

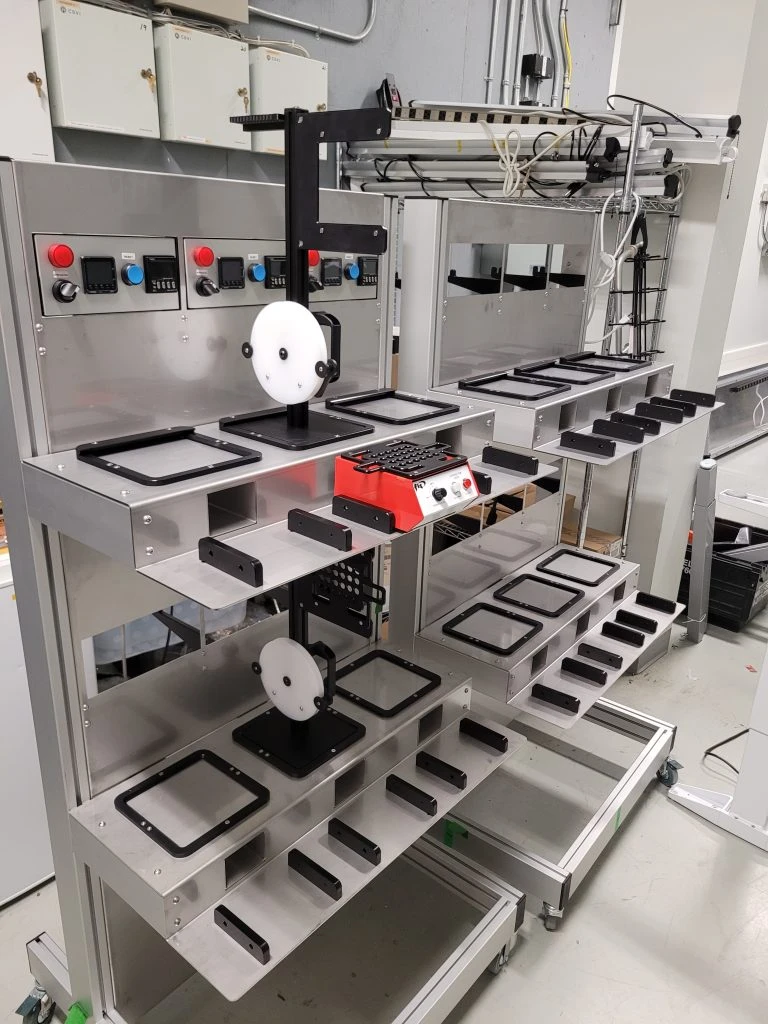

The project may look rather simple in the photo, but behind the scenes there were many hours spent optimizing the process used by the customer. It was this study, carried out in conjunction with the customer, that led to the final solution being simple, effective and within budget.

The shelves are suitable for the biomedical environment: easy to clean, stainless steel surface (made from folded, laser-cut sheets).

The structure is made of aluminum extrusions from MayTec.

Some parts had to be machined from aluminum, then anodized, to reduce the build-up of static electricity on the parts.

The result was welcomed by the project manager: the cycle time was reduced by a factor of 4, and the station was aesthetically pleasing, compact, mobile and ergonomic for the operators.

Other challenges included handling the optical fibers (hair-like in diameter) without damaging their ends or breaking them. We had to facilitate the management of 24 1m-long fibers on a surface area of 10cm squared.

What’s more, we intervened directly on the production line, without impacting on the production period, in a cleanroom environment.