The integration of automated solutions represents the application of technologies to control and monitor production processes without human intervention. These technologies include

This approach aims to increase the efficiency, precision and safety of industrial operations, while reducing costs and reliance on manual labor. By integrating automated systems, industries can optimize their workflows, improve product quality, and adapt quickly to changes in demand, ensuring greater competitiveness in the marketplace.

Creativity, simplicity and functionality go into every machine we build. Our expertise in mechanical design and prototyping has enabled us to carve out an enviable place in the Quebec market. If the ideal machine or product doesn’t exist, leave it to us to develop it with you.

Project management and documentation are fundamental aspects of any industrial process.

The ability to manage resources effectively, track project milestones and document the various phases are essential to ensure successful project completion.

Process optimization is a constant objective for industrial companies. This involves the analysis and continuous improvement of production processes to increase efficiency, reduce costs and minimize errors.

Process optimization means faster, more accurate and more profitable results.

Integration and design services are turnkey. We are involved from the drawing up of specifications through to validation and commissioning.

Our engineering project realization process is constantly evolving to offer quality service and up-to-date solutions.

For projects requiring a high degree of regulatory documentation, we work with companies specializing in quality control and validation.

To ensure the sustainability of each project, we implement a strategy that consists of :

UV Treatment

UV Treatment

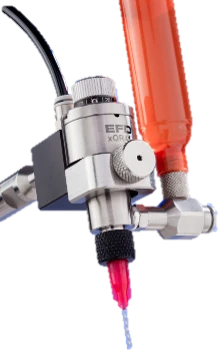

Glue and Wax dispensing

Glue and Wax dispensing

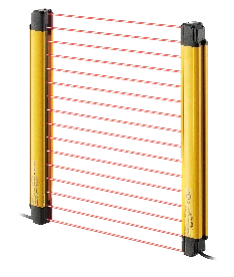

Security

Security

Sensors (level, flow, distance)

Sensors (level, flow, distance)

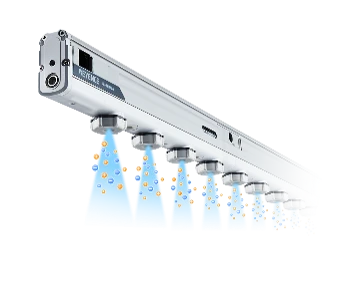

Air knife / Ion bar

Air knife / Ion bar

Pick’n’place

Pick’n’place

Precise & automated dispensing

Precise & automated dispensing

Spray/Spinner

Spray/Spinner

Leak test

Leak test

Plasma treatment

Plasma treatment

Temperature control

Temperature control

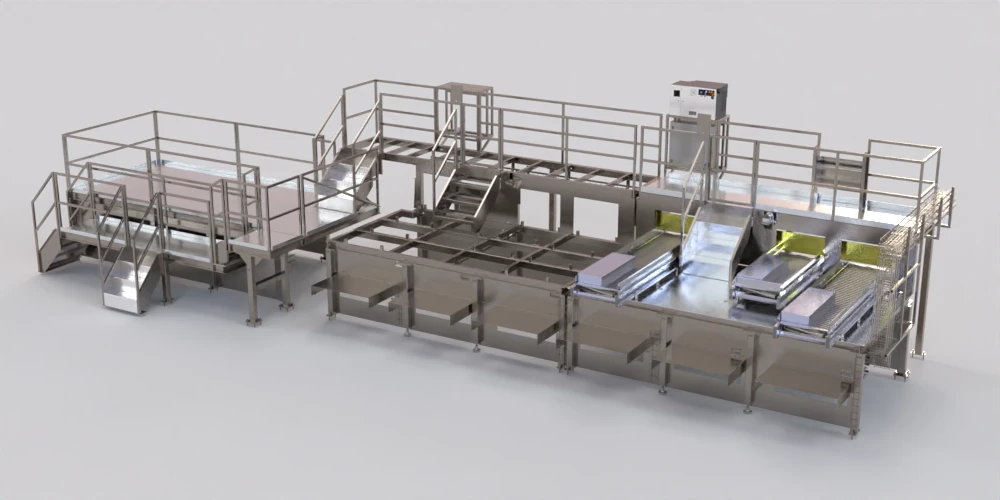

Cleanroom work is our specialty, and everything that goes with it. From the outset, FX-DX has specialized in engineering projects in the fields of bio-medicine, medical devices, life sciences and biotechnologies.

From the installation of production lines to the integration of aseptic isolators and the optimization of your processes, our team is accustomed to working on projects with demanding documentation and sanitary requirements.

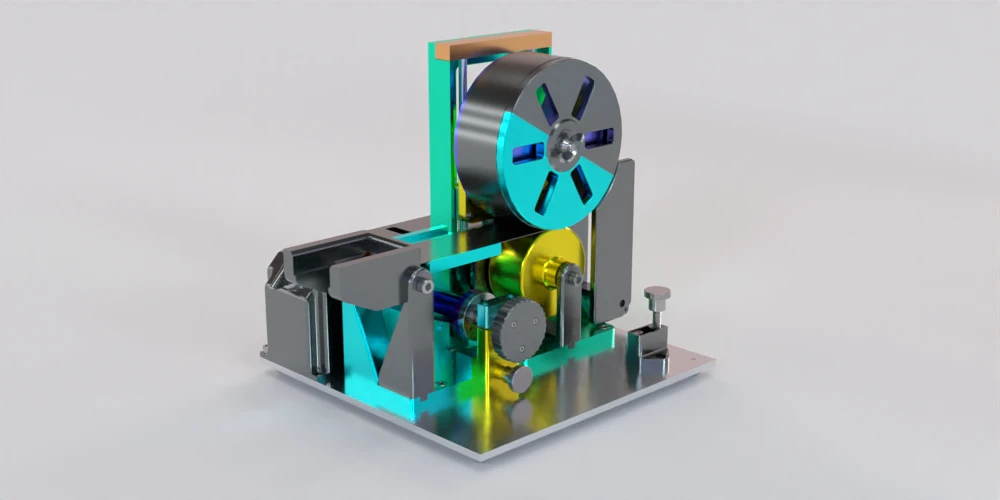

Discover our FX semi-autonomous stations, specifically designed for the pharmaceutical and medical industries.

When it comes to the food industry, our engineering services are focused on improving the quality, safety and efficiency of production processes.

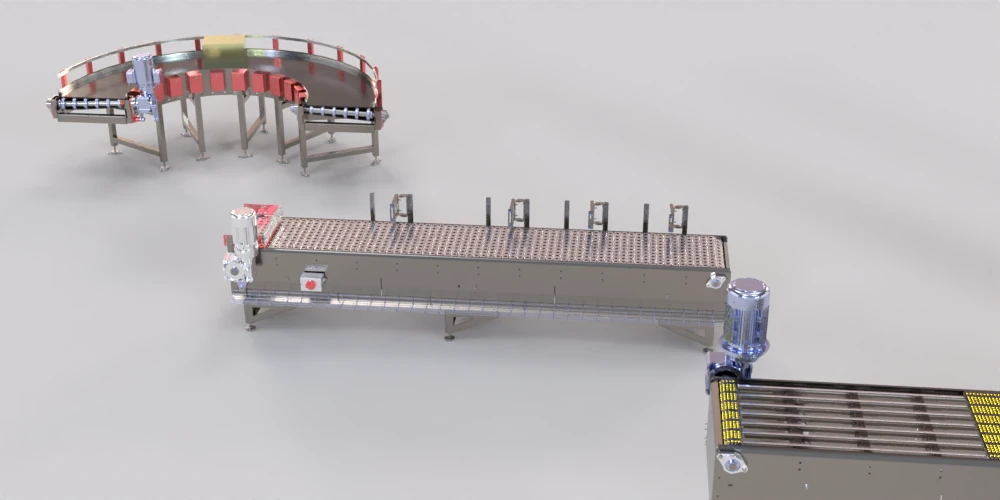

We are involved from the moment your product is packaged, right through to delivery. The integration of conveyors, palletizing systems, packaging machines, reject stations, scales and barcode identification are just some of the solutions we offer to help you achieve your profitability objectives.

Many applications require constant interaction between operators and robots. FX stations optimize your production rate while keeping operators safe.

There are many advantages to integrating FX stations:

Known starting price, adapted to your process, configurable to your needs, rapid integration. Designed for cleanrooms, pharmaceuticals, life sciences, biomedical and electronics.