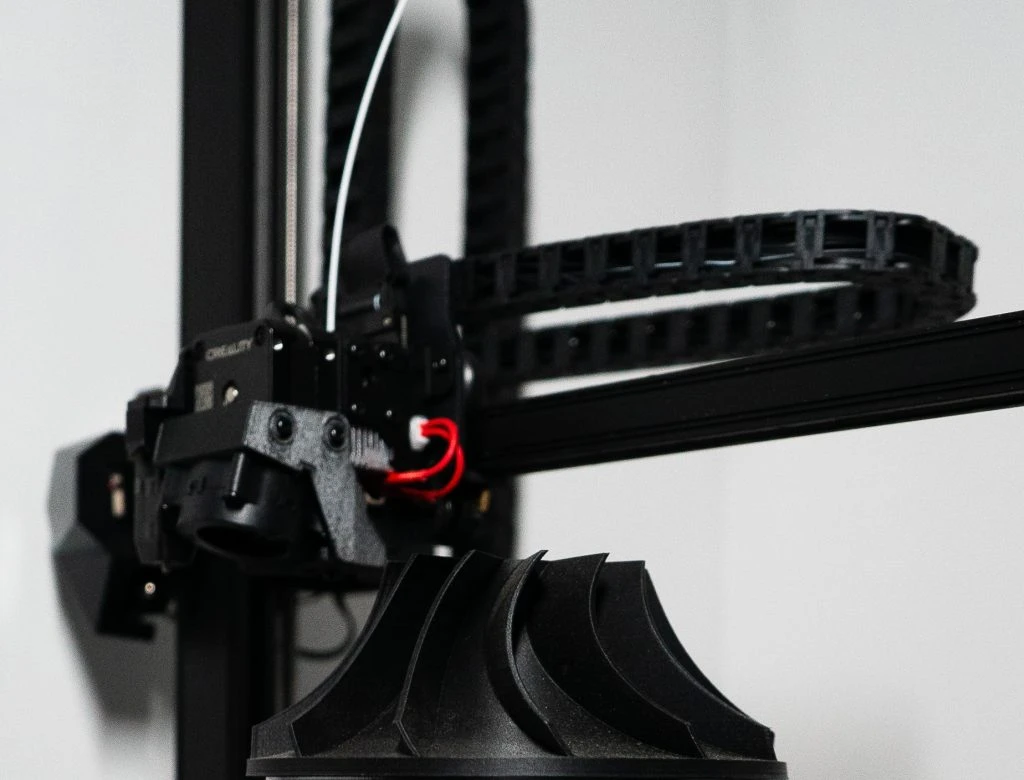

Our fleet of FDM and SLA 3D printers speeds up development and production.

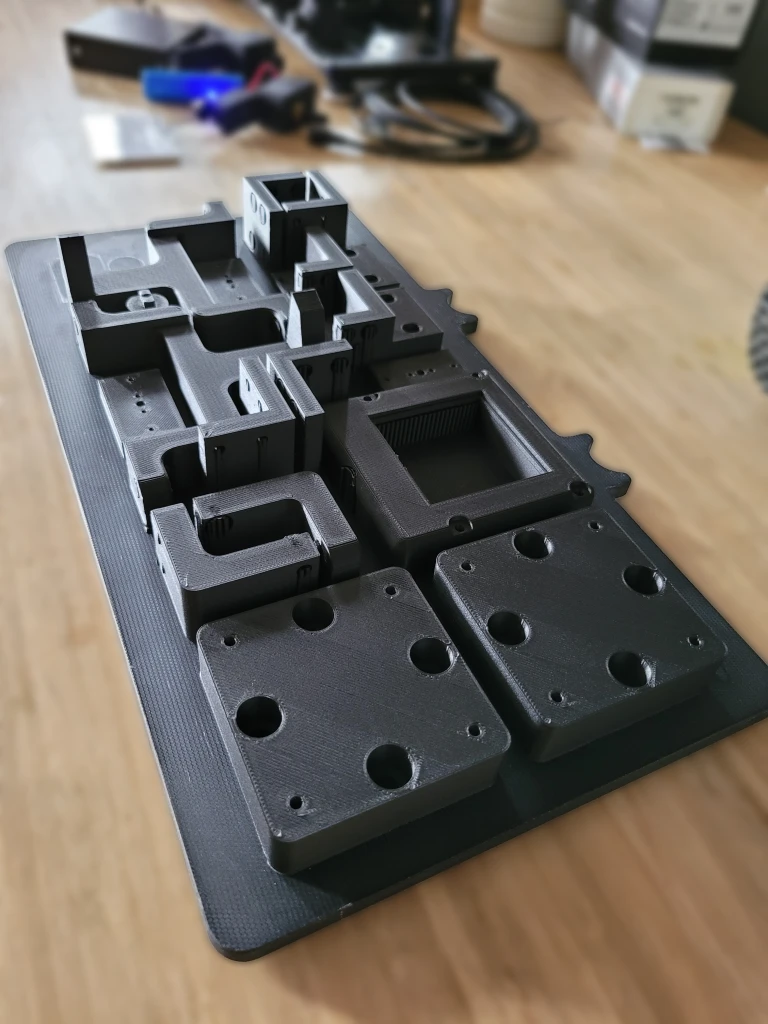

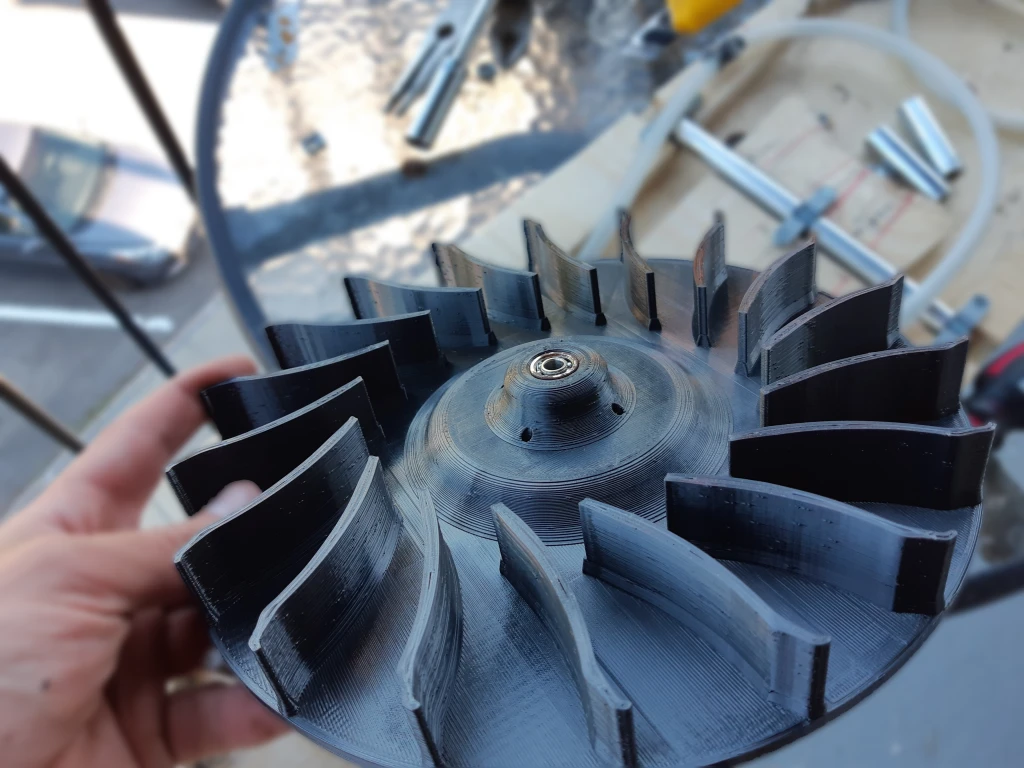

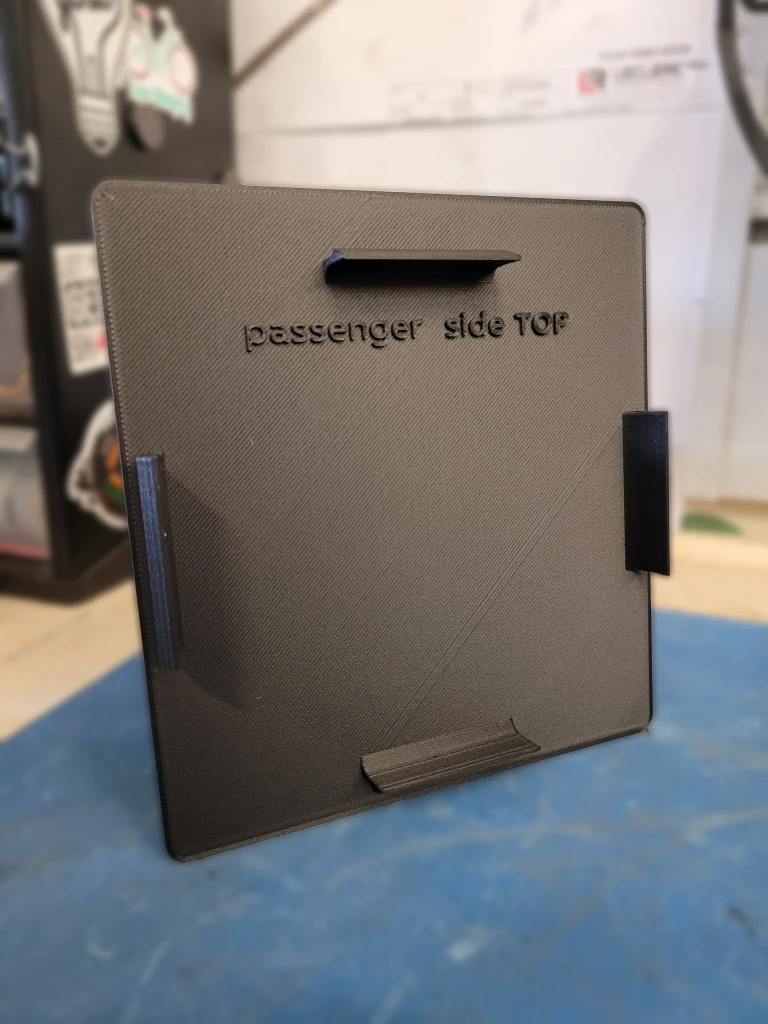

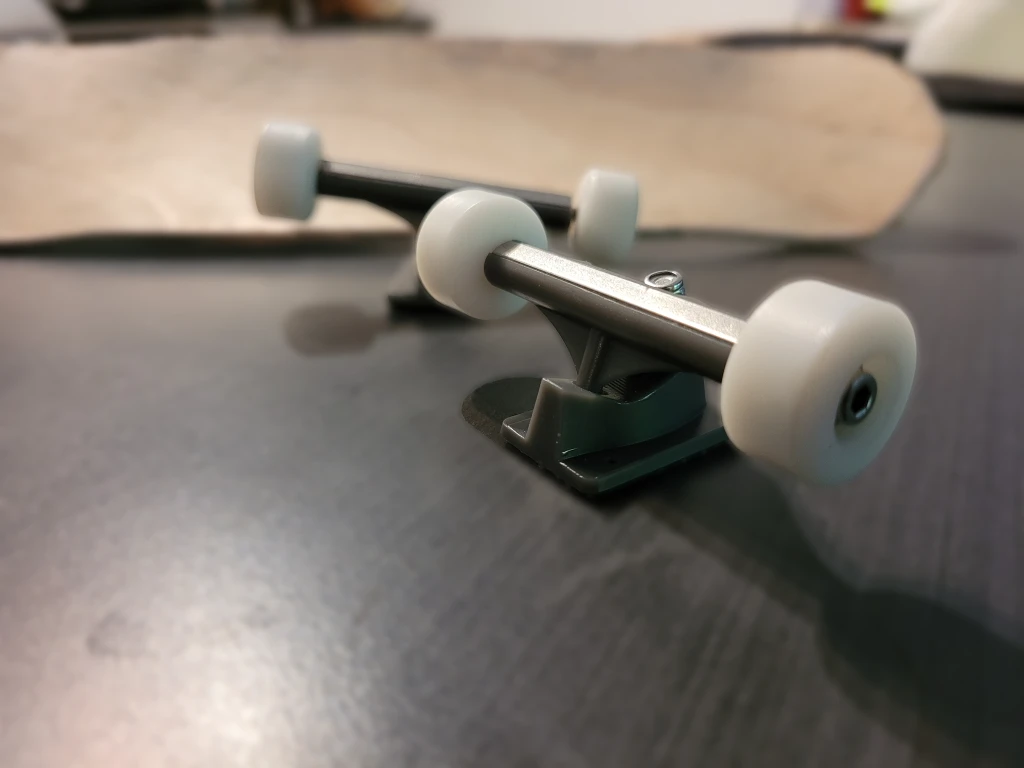

FDM (Fused deposition modeling) – involves the extrusion of thermoplastic filaments through a heated nozzle. This technique deposits the material layer by layer on a build platform, hardening almost immediately after extrusion to create a 3D object. It is renowned for its ability to produce functional parts and prototypes quickly and cost-effectively.

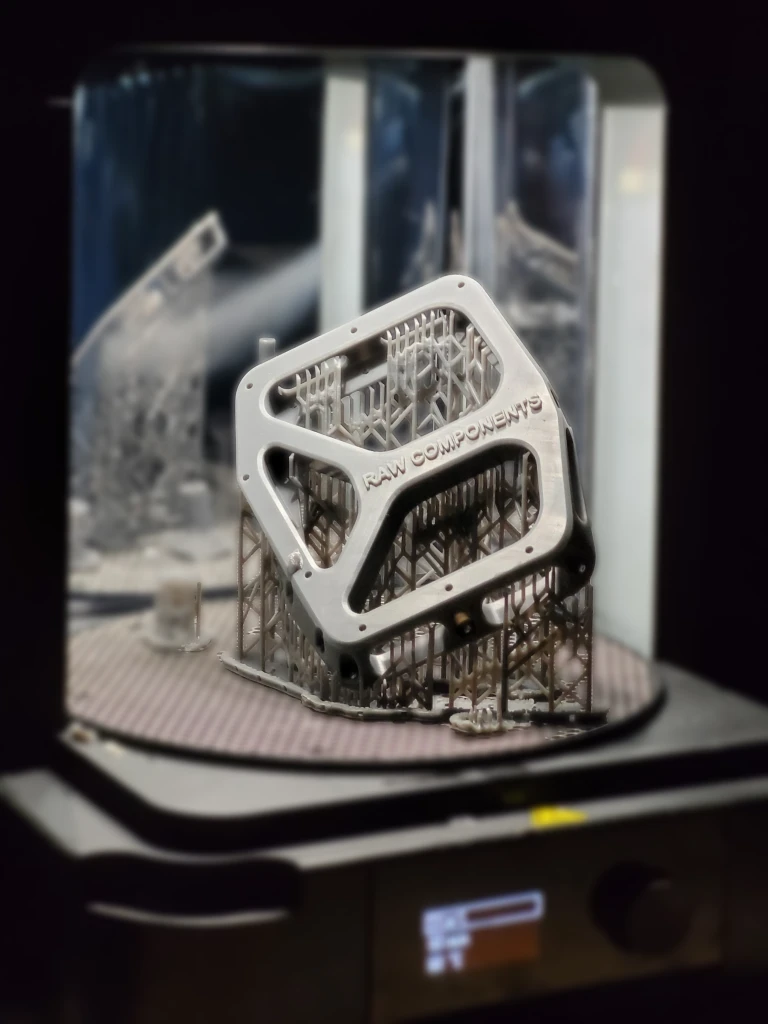

SLA ( Stereolithography) – Uses an ultraviolet laser to selectively solidify a photosensitive liquid, layer by layer, to form 3D objects. This process is known for its high precision and ability to produce smooth surfaces, making it ideal for prototypes, models and parts requiring fine detail.

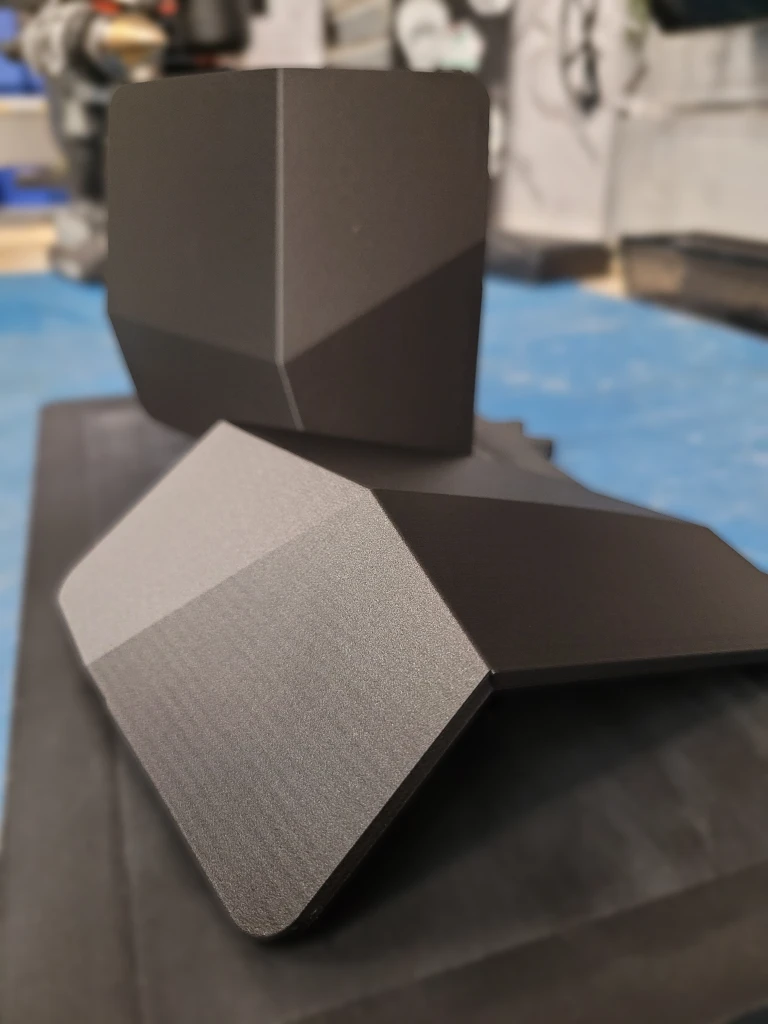

Different engineering resins are available: ceramic, flexible, foundry mold, and for various fields (dental, medical, food, aerospace).

Parts requiring one of these processes are processed rapidly. The work is carried out by our qualified local partners.

Reduced production times and costs thanks to rapid design and prototyping

Ability to quickly iterate on designs and test ideas

Easy customization of designs according to customer needs

Reduce production risks by allowing prototypes to be tested before going into production.

“ On-time delivery and professional service! ”

“ Our company often resorts to 3D printing for certain very specific parts, and although we have our own printers, we often do business with FX-DX for the print quality of their machines as well as their choice of materials, in addition to always having fast and impeccable service. I highly recommend FX-DX! ”

“ Mihail was able to put us at ease and guide us through the 3D modeling process, taking into account the limitations of the 3D printing process. The results lived up to our expectations. This first 3D printing project was a great success. ”

“ ULTRA FAST service! I had my parts in less than 24h! Perfect surface finish with SLA, it looks like an injected part! I recommend 100%! ”