Perhaps the biggest project we worked on was the design, production and installation of an accumulation line to automate the palletizing of chocolate boxes. The project took 1 year to complete and presented a number of technical and engineering challenges.

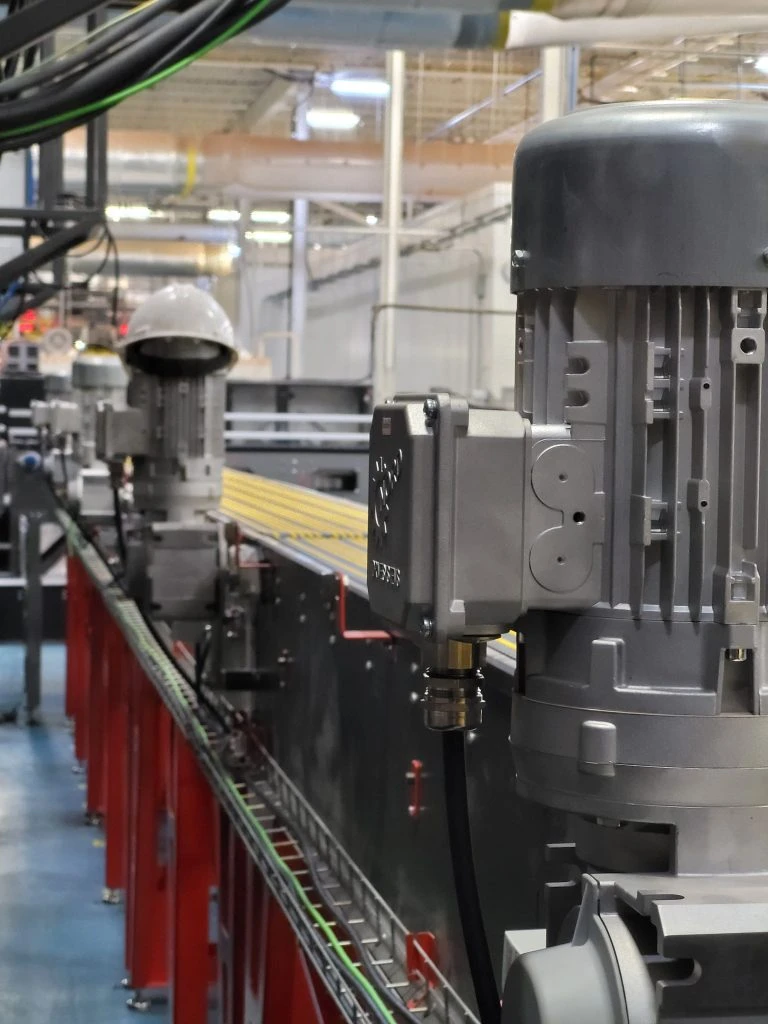

Leclerc Robotique commissioned us to design and put into production 22 conveyors, 5 Mezzanines, 1 specialized structure, and to develop other solutions within a very tight schedule.

Each conveyor had a different configuration (length, width, height, belt type, inclination, power, speed).

The mezzanines provided safe passage for operators, a tunnel for the distribution shuttle, and a structure for the robot infeed conveyors!

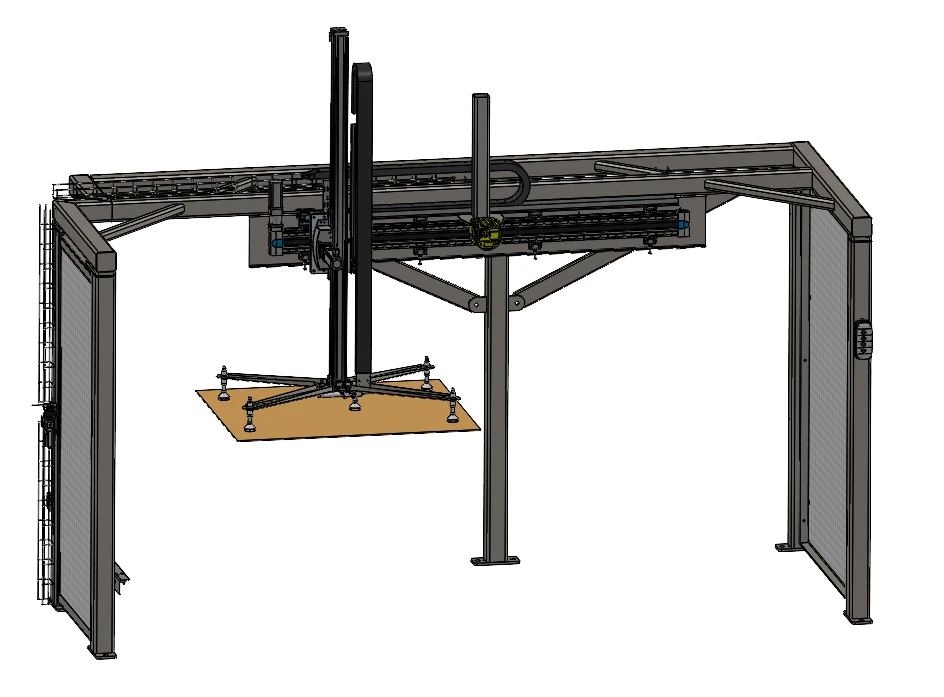

The specialized structure was used to mount a Festo two-axis robotic system, designed to load sheets of cardboard onto wooden pallets.

The accumulation line consisted of various types of conveyor: 180 degrees, up, down, active transfer, passive transfer. What these conveyors have in common is their modular belt. This technology, unique to Intralox, allows a multitude of belt configurations: rollers (accumulation), rubber (friction), flat (transport, positioning).

Laser cutting, water-jet cutting, sheet-metal bending, machining, MIG welding and powder-coating are the techniques used to manufacture conveyors and Mezanines.

Our team was able to deliver all the machines required to start up the palletizing warehouse.

For the customer, our “turnkey” approach was greatly appreciated, as we took charge of all operations, from design, through production start-up, right up to installation follow-up. Leclerc Robotique was responsible for manufacturing the machined, bent and laser-cut parts.

Throughout the project, FX-DX was able to proactively adapt to constantly changing layout configurations.